JSH150 Series Marking Tapes - Professional Industrial PVC Marking Solutions

| application | Warning tape |

| carrier | PVC |

| caliper | 131~150μm |

| construction | Single-side Tape |

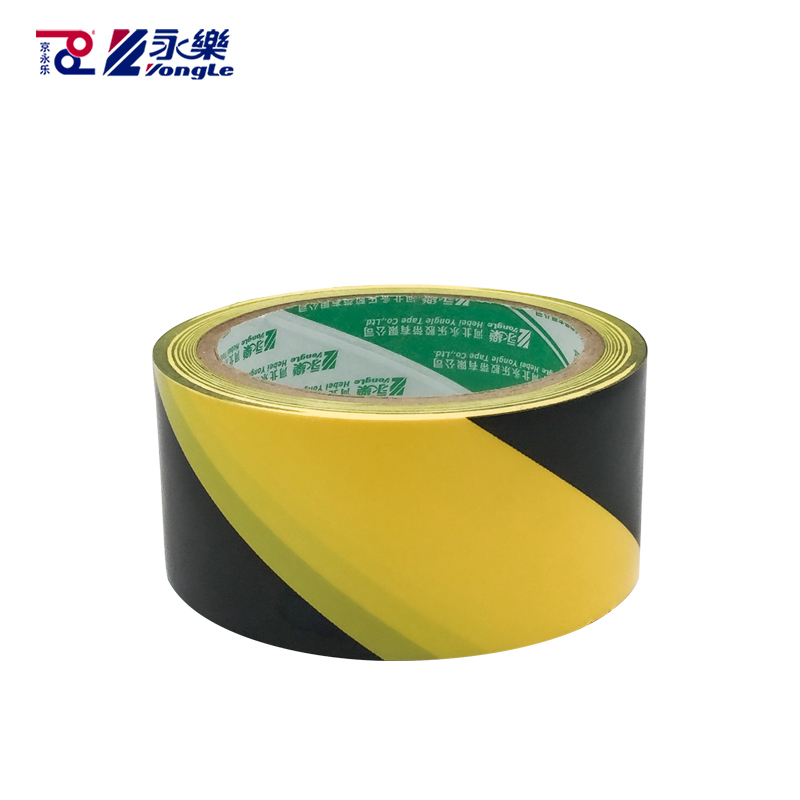

Dual-Color PVC Industrial Floor Marking Tape - Professional Grade Safety Floor Tape for Facility Management

Product Overview

Dual-Color PVC Industrial Floor Marking Tape represents the professional standard for facility safety marking and visual management systems. Engineered specifically for manufacturing plants, distribution centers, and industrial facilities, this high-performance safety floor tape delivers exceptional durability and clear visual communication for workplace organization and hazard identification.

Technical Specifications

Material Composition & Physical Properties

| Parameter | Specification | Testing Standard |

|---|---|---|

| Base Material | High-density PVC with UV stabilization | |

| Adhesive System | High-tack acrylic pressure-sensitive adhesive | |

| Total Thickness | 0.15mm ± 0.02mm | EN1942 |

| Available Widths | 50mm, 75mm, 100mm, 150mm (Custom widths 3mm-1260mm) | - |

| Roll Length | 33m standard (Custom lengths available) | - |

| Tensile Strength | ≥ 1.2 N/cm (Stainless steel, 20 minutes dwell) | ISO 29864 |

| Adhesion to Steel | ≥ 1.0 N/cm | ISO 29862 |

| Elongation at Break | ≥ 150% | ISO 29864 |

| Temperature Resistance | -20°C to +80°C continuous service | - |

| Tack | ≥6# | GB/T 4852 |

Performance Characteristics

Chemical Resistance:

Excellent resistance to water, oils, and mild industrial chemicals

Withstands occasional exposure to hydraulic fluids and lubricants

Surface Characteristics:

Matte finish reduces glare under industrial lighting

Medium traction surface for pedestrian safety

Low VOC compliant adhesive system

Color Coding & Safety Compliance

Standard Color Systems

Red & White Stripes

Application: Designates fire protection equipment, emergency stops, dangerous machinery

Compliance: ANSI Z535.1 safety color code for danger/don't enter

Recommended Use: Machine perimeter marking, electrical panel access zones

Yellow & Black Stripes

Application: Marks physical hazards, tripping dangers, protruding structures

Compliance: ANSI Z535.1 safety color code for caution/warning

Recommended Use: Stair edges, low overhead hazards, material handling paths

Green & White Stripes

Application: Identifies safety equipment, first aid stations, emergency egress

Compliance: ANSI Z535.1 safety color code for safety equipment/location

Recommended Use: Safety shower access, eyewash stations, emergency exit paths

Industrial Applications

Manufacturing & Production Facilities

Machine Guarding: Perimeter marking around robotic cells and automated equipment

Process Flow: Directional marking for material movement and workflow

Quality Zones: Designated areas for inspection, rework, and quarantine

Warehouse & Distribution Centers

Aisle Management: Clear traffic lane demarcation for pedestrians and equipment

Storage Zoning: Designated areas for raw materials, WIP, and finished goods

Loading Operations: Safe zones for dock operations and material transfer

Commercial & Institutional Facilities

Traffic Management: Corridor and doorway flow direction indicators

Maintenance Access: Utility access points and service equipment zones

Safety Compliance: OSHA and regulatory required markings

Installation Protocol

Surface Preparation Requirements

Concrete Substrates:

Surface profile: CSP 1-3 preferred

Moisture content: < 75% RH (ASTM F1869)

Surface cleanliness: SSPC-SP1 solvent cleaning standard

Resilient & Hard Flooring:

Secure, fully adhered surface required

Free of waxes, sealers, and dressings

pH neutral surface condition

Installation Procedure

Layout & Measurement

Use chalk lines or laser alignment for precision

Verify compliance with facility safety plans

Application Process

Maintain consistent tension during application

Use professional application tools for optimal results

Overlap ends by 2cm for continuous appearance

Post-Installation Requirements

Allow 45-minute initial set time before light traffic

24-hour full cure before heavy equipment traffic

Ambient temperature 15°C-35°C during installation

Performance Comparison

Technical Advantage Analysis

| Performance Metric | Dual-Color PVC Tape | Paint-Based Markings | Pre-formed Plastic |

|---|---|---|---|

| Installation Time | 15 min/30m | 120+ min/30m (incl. prep/dry) | 20 min/30m |

| Cure Time | 45 min to traffic | 4-24 hours to traffic | Immediate |

| Surface Preparation | Solvent clean | Mechanical prep often required | Solvent clean |

| Flexibility | Excellent - conforms to minor irregularities | Poor - cracks with substrate movement | Good |

| Replacement Ease | Peel and replace | Grind/re-prep/repaint | Peel and replace |

| Life Cycle Cost | $0.85/sq.ft./year | $1.20/sq.ft./year | $1.05/sq.ft./year |

Customer Reviews

⭐⭐⭐⭐⭐

Michael T. - Warehouse Manager, Germany

"Perfect for our distribution center floor marking! The white/red combination provides excellent visibility, and the adhesive holds strong even with constant forklift traffic. Much more durable than painted lines."

⭐⭐⭐⭐⭐

Sarah Chen - Sports Center Owner, Australia

"Excellent for basketball court lines! The tape conforms perfectly to our wooden floor without peeling. The dual-color design makes our courts look professional. No issues after 6 months of heavy use."

⭐⭐⭐⭐

David Rodriguez - Safety Officer, USA

"Reliable industrial tape that meets our safety standards. The black/yellow for hazard areas has significantly improved workplace safety. Surface preparation is crucial for optimal adhesion."

⭐⭐⭐⭐⭐

Emma Wilson - Event Planner, UK

"Game-changer for temporary event markings! Easy to apply by hand and removes cleanly without residue. The color coding helps us manage different zones efficiently during large events."

⭐⭐⭐⭐

James Kim - Maintenance Supervisor, South Korea

"Consistent performance in our manufacturing environment. The 30m length is practical for long runs. Would appreciate additional width options for different applications."

Q1: What surfaces does JSH150 adhere to best?

A: JSH150 provides excellent adhesion to concrete, epoxy floors, wood, vinyl, ceramic tile, and metal surfaces. For optimal results, ensure surfaces are clean, dry, and free from contaminants.

Q2: How does it handle heavy forklift traffic?

A: The industrial-grade PVC and rubber adhesive withstand moderate to heavy traffic. For maximum durability in high-traffic areas, we recommend edge sealing and proper surface preparation.

Q3: Is this suitable for outdoor applications?

A: Yes, it offers good weather resistance, but for permanent outdoor use we recommend our specialized outdoor-grade tapes with enhanced UV protection and waterproof properties.

Q4: What's the minimum order quantity for custom colors?

A: Custom color orders require minimum 500 rolls. Contact our international sales team for specific requirements, pricing, and lead times.

Q5: How do I remove the tape without surface damage?

A: Apply low heat with a heat gun to soften adhesive, then peel slowly at a 45-degree angle. Always test removal on a small area first, especially on sensitive surfaces.

Buying Guide

How to Choose the Right Tape

Narrow (3–10cm): Ideal for borders and small item zones.

Medium (10–30cm): Perfect for aisles and work cells.

Wide (30cm+): Best for large areas and strong visual cues.

Customization Options

Custom widths and lengths available.

Logo printing for branded floor marking solutions.

Ordering Information

Standard Packaging

Individual rolls: 16/22/33 meters, poly-bagged with core

Case quantities: 54/72 rolls per case, palletized options

Bulk orders: Direct container loading available

Lead Times

Standard products: 7-15 business days

Custom widths/colors: 10-20 business days

Large projects: Project-based scheduling