YONGLE 8888 PVC Dry Vinyl Tape - Non-Adhesive Wire Harness Tape 85℃

| application | Wire harness tape |

| carrier | PVC |

| caliper | 101~130μm |

| construction | Dry Tape |

| compliace | RoHS, REACH |

| performace_feature | Low VOC/Odor, Flame Resistant |

| heat_resistance | 85℃ |

YONGLE 8888 PVC Dry Vinyl Tape is a premium non-adhesive soft PVC tape specifically engineered for automotive wire harness wrapping and industrial protection. Crafted with high-quality PVC as the carrier, it supports both manual and mechanical operations, delivering reliable performance in conventional temperature environments. Unlike adhesive tapes, it leaves no residue and clings securely to itself, ensuring precise and clean wrapping for delicate components. Fully compliant with RoHS and REACH standards, this tape meets global environmental and safety regulations, making it a trusted choice for the automotive wire harness industry and industrial applications worldwide.

Core Advantages

·Non-Adhesive Design: Eliminates adhesive residue and glue migration, enabling precise application for delicate wire harnesses and easy post-maintenance.

·Flame Retardant Performance: Class B self-extinguishing property (meets GMW 16740/LV 312 standards), reducing electrical hazard risks in wiring systems.

·Excellent Conformability: Soft PVC material fits tightly to complex shapes and wire harnesses, preventing unraveling during use.

·Dual Application Compatibility: Suitable for both manual and mechanical operations with controlled, uniform unwind, adapting to small-batch precision wrapping and large-scale production needs.

·Global Regulatory Compliance: RoHS & REACH certified, ensuring accessibility to global markets and meeting environmental safety requirements.

·Customizable Solutions: Tailored sizes, colors, and specifications available to match unique user application needs.

Technical Specifications:

Property | Unit | Typical data | Test Method |

Total Thickness | mm | 0.12±0.02 | EN 1942 |

Tensile Strength | N/cm | > 20 | ISO 29864 |

Elongation at break | % | > 250 | ISO 29864 |

Adhesion strength | QCT-906(24fts/min) | ||

---hand taping | Oz/19mm | 20-40 | |

N/19mm | 5.5-12.1 | ||

Oz/25mm | 20-40 | ||

N/25mm | 5.5-12.5 | ||

Flammability | - | B (Self-Extinguishing) | GMW 16740/LV 312 |

Breakdown voltage | kV | 5.5 | ASTM D1000 |

Temperature rating | ℃ | B:-25-85 | GMW 16740 / LV 312 |

Applications

Recommended Uses

·Automotive Wire Harness Protection:Provides permanent shielding for wire harnesses against vibration, abrasion, and environmental factors in vehicle environments.

·Industrial Electroplating Masking: Precision masking to protect non-target surfaces from corrosion by plating solutions.

·Cable Insulation: Offers reliable electrical insulation for general-purpose cables, compatible with its 5.5kV breakdown voltage.

·Mechanical Component Bundling: Secure wrapping for regular-shaped mechanical parts requiring durable fixation.

Specifications & Customization

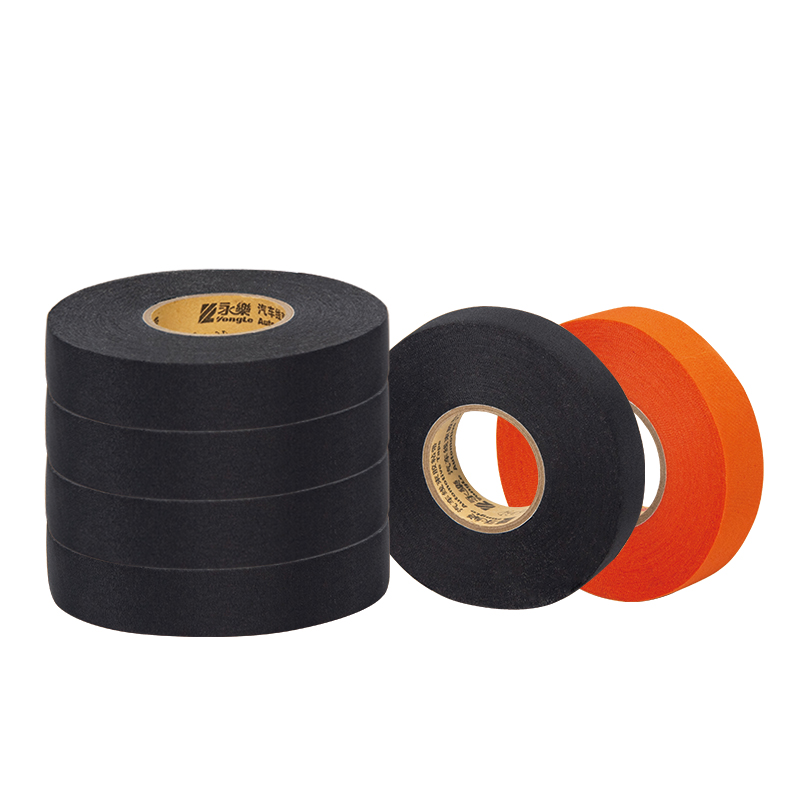

·Standard Colors: Black, White, Yellow (Custom colors available upon request).

·Dimensions:

◆Length: 33m, 40m

◆Width: 19mm, 25mm

◆Paper Core Inner Diameter: 38mm

·Custom Solutions: Tailored thickness, width, and flame retardancy levels for industrial OEM requirements.

Storage & Shelf Life

Shelf Life: 1 year when stored under recommended conditions.

Storage Requirements:

Temperature: 20-30℃ (avoid direct exposure to heat sources);

Humidity: Maximum 65% relative humidity;

Packaging: Keep in original sealed packaging and away from direct sunlight to prevent material aging and color fading.

1. A Backbone for Large-Scale Automotive Harness Production!

Robert Carter - USA - Global Automotive Parts Production Director

★★★★★

2. Trusted Insulation for Industrial Control System Harnesses!

Andreas Müller - Germany - Industrial Control System Engineer

★★★★★

3. Go-To Tape for National Auto Repair Chain!

Sophie Laurent - France - National Auto Repair Chain Procurement Manager

★★★★★

4. Essential Masking Solution for Large-Scale Electroplating Facilities!

Rajiv Mehta - India - Large-Scale Industrial Electroplating Plant Manager

★★★★★

5. Reliable Protection for Marine Vessel Wire Harnesses!

Carlos Mendez - Brazil - Marine Vessel Manufacturer

★★★★★