E810 PET Cloth Wire Harness Tape - Low VOC, Hand-Tearable, 125℃ Resistance

| application | Wire harness tape |

| carrier | Cloth |

| caliper | 101~130μm |

| construction | Single-side Tape |

| compliace | RoHS, CSA, REACH |

| performace_feature | Low VOC/Odor, Flame Resistant |

| heat_resistance | 125℃ |

Product Introduction: E810 PET Cloth Automotive Wire Harness Tape

E810 is a PET cloth-based automotive wire harness tape specifically designed for the automotive industry. It uses high-quality PET cloth as the carrier, paired with a strong acrylic adhesive, and features key advantages such as easy hand tearability, a durable and stain-resistant surface, and high temperature resistance up to 125℃. The product strictly complies with multiple international authoritative certification standards including RoHS, CSA, and REACH. With excellent wear resistance, high-temperature stability, and media resistance, it serves as a high-quality choice for automotive wire harness wrapping, suitable for application in all parts of vehicles.

| Item | Details |

|---|---|

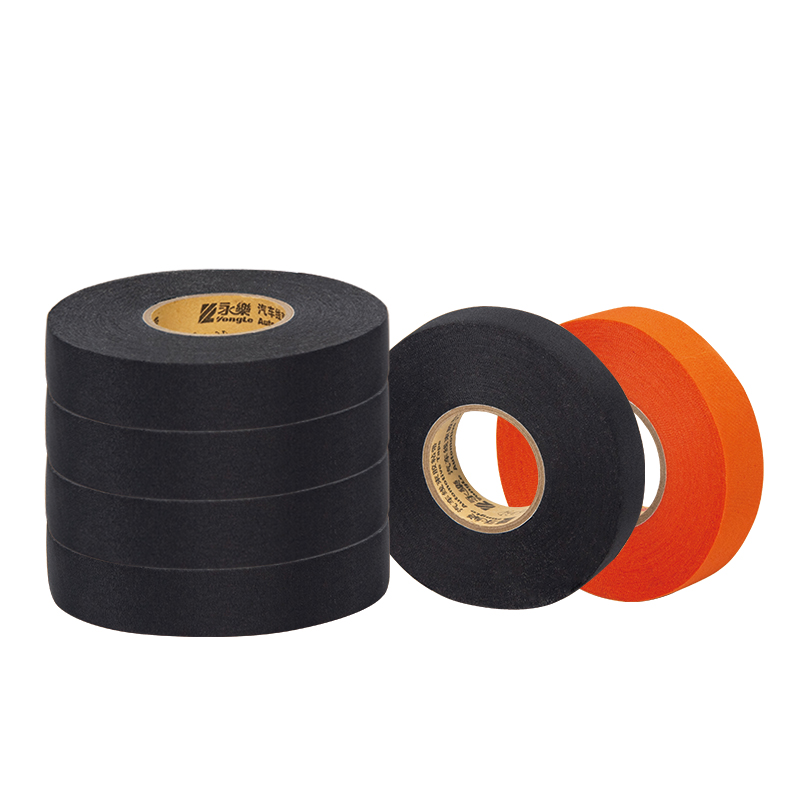

| Color | Black (other colors available on request) |

| Length | 20m, 25m |

| Width | 19mm, 25mm |

| Core Inner Diameter | 38mm |

| Structure | Single-sided Tape |

| Compliance Certifications | Meets relevant industry standards (EN, ISO, GMW) |

Acrylic adhesive

PET cloth carrier

Single-side tape design

Low VOC emissions + low odor, meeting eco-friendly requirements

Hand-tearable for convenient and efficient construction

Excellent wear resistance for longer service life

Strong high-temperature resistance (-40~125℃)

Outstanding chemical resistance, resisting medium corrosion

Flexible and easy to handle, adapting to complex wire harness routes

Compatible with both machine processing and manual operation

| Property | Value | Unit | Test Method |

|---|---|---|---|

| Total Thickness | 0.180±0.03 | mm | EN 1942 |

| Tensile Strength | >65 | N/cm | ISO 29864 |

| Elongation at Break | >10 | % | ISO 29864 |

| Adhesion Strength - to Steel | >1.5 | N/cm | ISO 29862 |

| Adhesion Strength - to Backing | >1.5 | N/cm | ISO 29862 |

| Unwind Force | 2.0~6.0 | N/cm | EN 1944 |

| Flammability | B (self-extinguishing) | - | GMW 16740 / LV 312 |

| Abrasion Resistance (φ5mm) | B: 100~499 | cycles | ISO 6722 / GMW 16740 / LV 312 |

| Noise Dampening | A: 0~2 | dB(A) | GMW 16740 / LV 312 |

| Temperature Rating | C: -40~125 | ℃ | GMW 16740 / LV 312 |

Note: The listed values are for reference only and are not intended to serve as official product specifications.

E810 is preferably used for cable harnessing in the automotive industry. Its durable carrier fully meets the basic requirements for wear resistance of wire harnesses. Combined with its excellent high-temperature stability, ultra-durable carrier properties, and outstanding media resistance, this product can be applied to all parts of the vehicle (including the engine compartment, interior, and chassis), providing comprehensive protection and fixation for automotive wire harnesses.

Storage Conditions: Store in original packaging at 20-30℃, relative humidity ≤65%, away from direct sunlight.

Shelf Life: 2 years under the above storage conditions.

1.High-Temp Hero for Southeast Asian Automotive Production!

“Our automotive parts factory in Thailand faced constant issues with wire harness tapes softening in 40℃+ workshop temperatures—until we adopted YONGLE E810 High-Temp Automotive Wire Harness Tape. Its 125℃ heat resistance keeps it stable even near engine components, and the hand-tearable design speeds up assembly by 20% (no more utility knives!). The RoHS/REACH compliance lets us export to global markets, and the stain-resistant surface reduces rework from oil spills. It’s transformed our harness production line!”

– Production Manager, Automotive Parts Factory (Thailand)

★★★★★

2.Cold-Climate Savior for Nordic Automotive Harnesses!

“Our automotive factory in Sweden struggled with automotive wire harness tapes becoming brittle and cracking in -25℃ winter temperatures—until we switched to YONGLE E810. Its -40~125℃ temperature rating keeps the tape flexible even in Arctic-like conditions, and the PET cloth carrier resists wear from snow and road salt. The hand-tearable design cuts on-site repair time by 22%, and UL compliance lets us supply to North American markets. It’s the only tape we trust for cold-weather vehicle builds!”

– Production Engineer, Automotive Factory (Sweden)

★★★★★

3.Off-Road Harness Toughness for Australian 4x4 Customs!

“Our 4x4 customization shop in Brisbane builds off-road vehicles that face dust, mud, and 45℃ heat—our old tapes would fail within months. YONGLE E810 changed that: its stain-resistant surface repels mud and dust, and the 125℃ heat resistance handles outback temperatures. The noise dampening (0~2 dB(A)) reduces cabin wire rattle on rough terrain, and the tape’s durability has extended harness life by 50%. It’s built for the harshest off-road conditions!”

– Owner, 4x4 Off-Road Custom Shop (Australia)

★★★★★

4.Oil-Resistant & Fire-Safe for Indian Engine Bay Harnesses!

“Our automotive factory in New Delhi fought with wire harness tapes breaking down in engine bay oil—until we switched to YONGLE E810 Low VOC Wire Harness Tape. Its outstanding chemical resistance repels oil and grease, and the 125℃ heat resistance handles our summer under-hood temps. Class B flame retardancy meets our strict safety standards, and the PET cloth’s durability has cut harness failures by 30%. It’s the most reliable automotive wire harness tape we’ve used!”

– Quality Manager, Automotive Factory (India)

★★★★★

5.Machine-Friendly Tape That Cuts Downtime for Large-Scale Harnesses!

“Our automotive assembly plant in Michigan struggled with tape jamming on automated wire harness machines—until we tried YONGLE E820 PET Cloth Automotive Tape. Its 2.0~6.0 N/cm unwind force is perfect for our high-speed lines, reducing downtime by 25%. The >65 N/cm tensile strength resists tearing, and the chemical resistance stands up to factory coolants. As a bonus, the low VOC odor makes our workshop safer—this tape checks every box for mass production!”

– Operations Manager, Automotive Assembly Plant (Michigan)

★★★★★

Frequently Asked Questions

Everything you need to know about YONGLE E810 Auto Wire Harness Tape