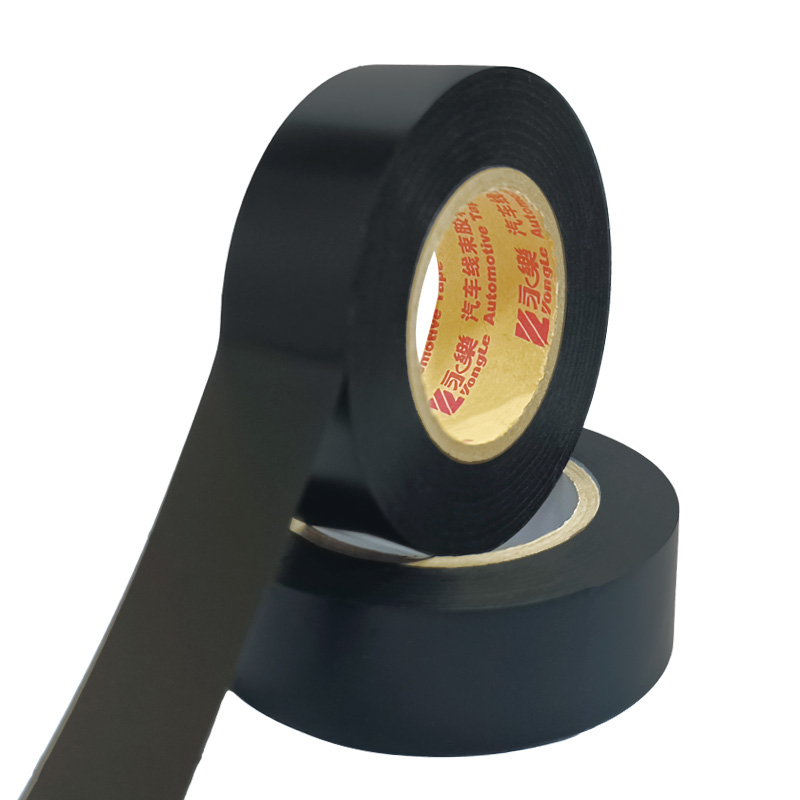

FC150 Colored PVC Harness Wrap Tape - Flame Resistant 105°C

| application | Wire harness tape |

| carrier | PVC |

| caliper | 131~150μm |

| construction | Single-side Tape |

| compliace | RoHS, REACH |

| performace_feature | Low VOC/Odor, Flame Resistant |

| heat_resistance | 105℃ |

Yongle FC150 Colored Harness Wrap Tape is a high-performance adhesive tape designed for permanent wiring harness wrapping, backed by the credibility of a Chinese Top Brand and Chinese Trade Mark. Crafted with high-quality soft PVC film as the carrier and coated with a strong rubber-based adhesive, this hand-applicable tape delivers reliable performance even in extreme environmental conditions, with a temperature rating of -25~105℃. It

combines flexibility, durability, and compliance with international standards, making it the preferred choice for critical applications across multiple industries.

Key Features

Rubber-based adhesive for strong, long-lasting bonding

Soft PVC carrier ensures excellent flexibility and conformability

Flame-resistant (B-class self-extinguishing rating per ISO 3795)

Controlled, even unwind for smooth application

Fully compliant with RoHS & REACH environmental regulations

Hand-applicable design for convenience in various assembly scenarios

Core Benefits

Multiple color options (black, white, yellow, red, blue, green) for easy wiring identification

Highly conformable to wrap tightly around complex harness shapes

Exceptional durability for long-term reliability under varying temperature and environmental stress

Strong adhesion to both steel and tape backing (≥1.5 N/cm) for secure, permanent wrapping

Meets international test standards (ISO, EN, IEC, GMW) for consistent quality

Customizable sizes and colors available to match specific application needs

Available Colors & Sizes

Standard Colors

Black, White, Yellow, Red, Blue, GreenCustom colors available upon request

Standard Sizes

Length: 30.4m, 33m, 40m

Width: 19mm, 25mm

Core ID: 38mm

Custom sizes available for bulk orders

Recommended Applications

Ideal for permanent wrapping on wiring harnesses in:

Automotive manufacturing and assemblies

Agricultural equipment (tractors, harvesters, and outdoor machinery)

Aircraft and aerospace components

Electronic assemblies and consumer electronics

Industrial machinery and control systems

Especially preferred for applications requiring:

Color-coded wiring identification

Long-term reliability in extreme temperatures (-25~105℃)

Resistance to flame, moisture, and environmental wear

Compliance with global environmental and safety standards

Storage & Shelf Life

To maintain optimal performance, store the tape in its original packaging under the following conditions:

Temperature: 20-30℃ (68-86°F)

Relative humidity: Maximum 65%

Away from direct sunlight and heat sources

1. Low-Temp & Compliance Pro for European Automotive Harnesses!

“Our German automotive harness plant struggled with wire harness tapes cracking in -20℃ winter storage and failing EU environmental audits—until we switched to YONGLE FC150. Its -25~105℃ temperature range keeps the tape flexible even in cold warehouses, and 100% RoHS/REACH compliance clears all export barriers to the EU. The rubber adhesive bonds tightly to automotive wires without peeling, and the controlled unwind cuts wrapping time by 18%. We’ve reduced harness defect rates from 8% to 2%—it’s our trusted choice for premium vehicle wiring!”

– Quality Assurance Manager, Automotive Harness Supplier (Germany)

★★★★★

2. Flame-Resistant Workhorse for North American Heavy-Duty Trucks!

“Our Ohio factory manufactures heavy-duty truck harnesses, where fire safety and vibration resistance are non-negotiable. YONGLE FC150’s ISO 3795 B-class self-extinguishing rating meets DOT safety standards, and its ≥1.5 N/cm adhesion to steel withstands constant vehicle vibration. The hand-applicable design eliminates tool downtime, and the PVC carrier conforms perfectly to complex wire bundles—no gaps or lifting. Since adopting it, harness failure due to heat or vibration has dropped by 25%!”

– Production Engineering Supervisor, Heavy-Duty Truck Parts Manufacturer (USA)

★★★★★

3. High-Humidity Hero for Southeast Asian Auto Lines!

“Our Malaysian automotive component plant faces 35℃+ temperatures and 75% humidity year-round, which made traditional tapes lose adhesion in weeks. YONGLE FC150’s 105℃ heat resistance and moisture-resistant PVC carrier keep harnesses secure—even near engine bays. The 6 standard colors (black/white/yellow/red/blue/green) simplify wire identification, cutting assembly errors by 30%, and RoHS compliance lets us export to ASEAN and global markets seamlessly. Assembly efficiency is up 22% with zero rework from loose tape!”

– Operations Manager, Automotive Wiring Factory (Malaysia)

★★★★★

4. Efficient & Consistent Solution for Chinese Mass Production!

“Our Shanghai-based automotive plant produces 10,000+ harnesses daily—so speed and consistency matter most. YONGLE FC150’s hand-tearable design eliminates cutter use, speeding up wrapping by 20%, and its controlled unwind ensures uniform application across every roll. The ≥16 N/cm tensile strength resists tearing during high-volume assembly, and the 1-year shelf life lets us stock bulk inventory without quality loss. It’s helped us meet tight production deadlines while maintaining ISO 9001 quality standards!”

– Plant Manager, Automotive Harness Mass Producer (China)

★★★★★

5. All-Condition Reliability for Indian Automotive Assemblies!

“Our Bangalore factory supplies harnesses for both passenger cars and commercial vehicles, which face extreme heat (40℃+) and rough road vibration. YONGLE FC150’s -25~105℃ temperature range handles our climate perfectly—no softening in summer or brittleness in winter. The strong rubber adhesive stays bonded through vehicle lifespan, and RoHS compliance aligns with India’s BS6 emission norms. We’ve cut rework costs by 15% and improved on-time delivery by 12%—it’s the most consistent automotive harness tape we’ve tested!”

– Wire Harness Production Lead, Auto Component Manufacturer (India)

★★★★★

Frequently Asked Questions

Everything you need to know about YONGLE FC150 Auto Wire Harness Tape